New Chip Architectures for Industrial Vision

Objective

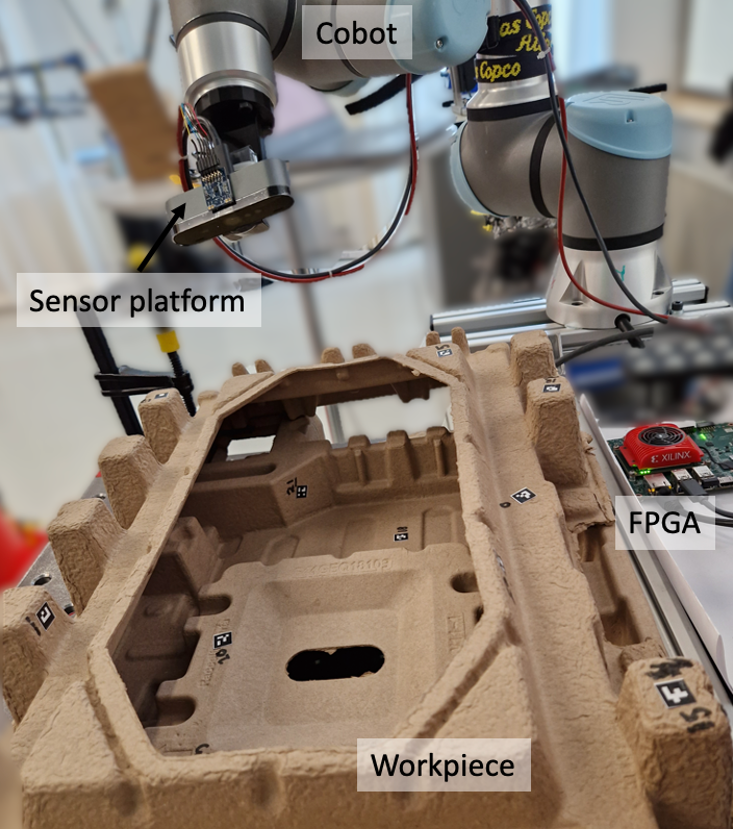

Atlas Copco is a world leader in safety-critical assembly tools widely used in industries like automotive, aviation, and mobile phones. To maintain its world-leading position, Atlas Copco would like to error-proof its handheld tightening tools to ensure that depending on the assembly, the bolts are tightened with the right tightening program and in the right sequence, and no bolts are left untightened. Atlas Copco would like to use an AI/ML-based sensor fusion system to achieve this. The form factor, power budget, latency, and cost requirements rule out the use of COTS like GPUs, TPUs, or FPGAs. ASICs (Application Specific Integrated Circuits) would meet these constraints, but they take too long, are very expensive, and require specialist competence that Atlas Copco lacks. KTH has developed a Lego-inspired design framework called SiLago that provides ASIC-comparable energy efficiency and form factor but allows non-specialists like mechatronic and AI/ML experts from Atlas Copco to create a ready-to-manufacture custom chip.

The objective of this demo project is to validate the claim of SiLago by showing that it can be used by non-specialists to implement this challenging AI/ML system and meet its constraints.

Background

Industry 4.0 or the Fourth Industrial Revolution refers to a significant transformation in how manufacturing and other industries operate, characterized by the integration of digital technologies, automation, data exchange, and smart systems. To align its product offerings with the Industry 4.0 vision, Atlas Copco has launched a pilot project to error-proof its tightening tools to improve the assembly process’s reliability, flexibility, and productivity. To achieve these objectives, it is developing an AI/ML-based sensor fusion system. Energy and cost-efficient implementation of such systems is a well-recognized challenge, and many large actors like Tesla, Google, etc. have opted for an ASIC-based design. However, the design cost of ASICs runs in 100s of MUSDs and requires large volumes and/or large profits to justify them. This often restricts ASICs as a solution to large actors.

To democratize access to ASIC-like efficiency for small actors and non-specialists, KTH has proposed a Lego-inspired design framework called SiLago. The impact of this demo project will be well beyond this specific use case from Atlas Copco; it will open the doors for ecologically and economically scalable energy-efficient digitalization in many sectors, including scientific super-computing.

Crossdisciplinary collaboration

This demo project spans multiple disciplines: mechatronics, AI and ML algorithms, sensor informatics, computer architecture, and VLSI design. It is a collaboration between KTH and Atlas Copco.

Contacts

Ahmed Hemani

Professor, Division of Electronics and Embedded Systems at KTH , PI: New Chip Architectures for Industrial Vision, Digital Futures Faculty

+46 8 790 44 69hemani@kth.se

Sofia Olsson

Industrial PhD Student, Atlas Copco, EES/EE, School of EECS, KTH, Co-PI: New Chip Architectures for Industrial Vision

sofia.olsson@atlascopco.com